Crack

Prohibition

Any Crack Shall be unacceptable, regardless of size

or Location.

Weld

Base Metal Fusion

Thorough fusion shall exit between adjacent layer of

weld metal and between weld metal and base metal.

Crater

Cross Section

All craters shall be filled to provide the specified

weld size, except for the ends of intermittent fillet welds outside of their

effective lengths.

Weld

Profiles

Weld profiles shall be in conformance with AWS D1.1

Sub section 5.24

Time

of Inspection

Visual inspection of welds in all steel may begin

immediately after the complete welds have cooled to ambient temperature.

Acceptance criteria for ASTM A 514, ASTM A 514 and A 709 Grade 100 and 100 W

steels shall be based on visual inspection performed not less than 48hours

after completion of welds.

Undersized

Welds

The size of fillet weld in any continuous weld may

be less than the specified nominal size (L) without correction by the following

amounts (U)

Specified

Weld Size (L) mm

Allowable decrease from (L) mm

Less than 5 mm 2 mm

6

mm

2.5 mm

Greater than 8 mm 3 mm

In all case, the undersize portion of the weld shall

not exceed 10% of the weld length, one web-flange welds on grinders, under run

shall be prohibited and for a length equal to twice the width of the length

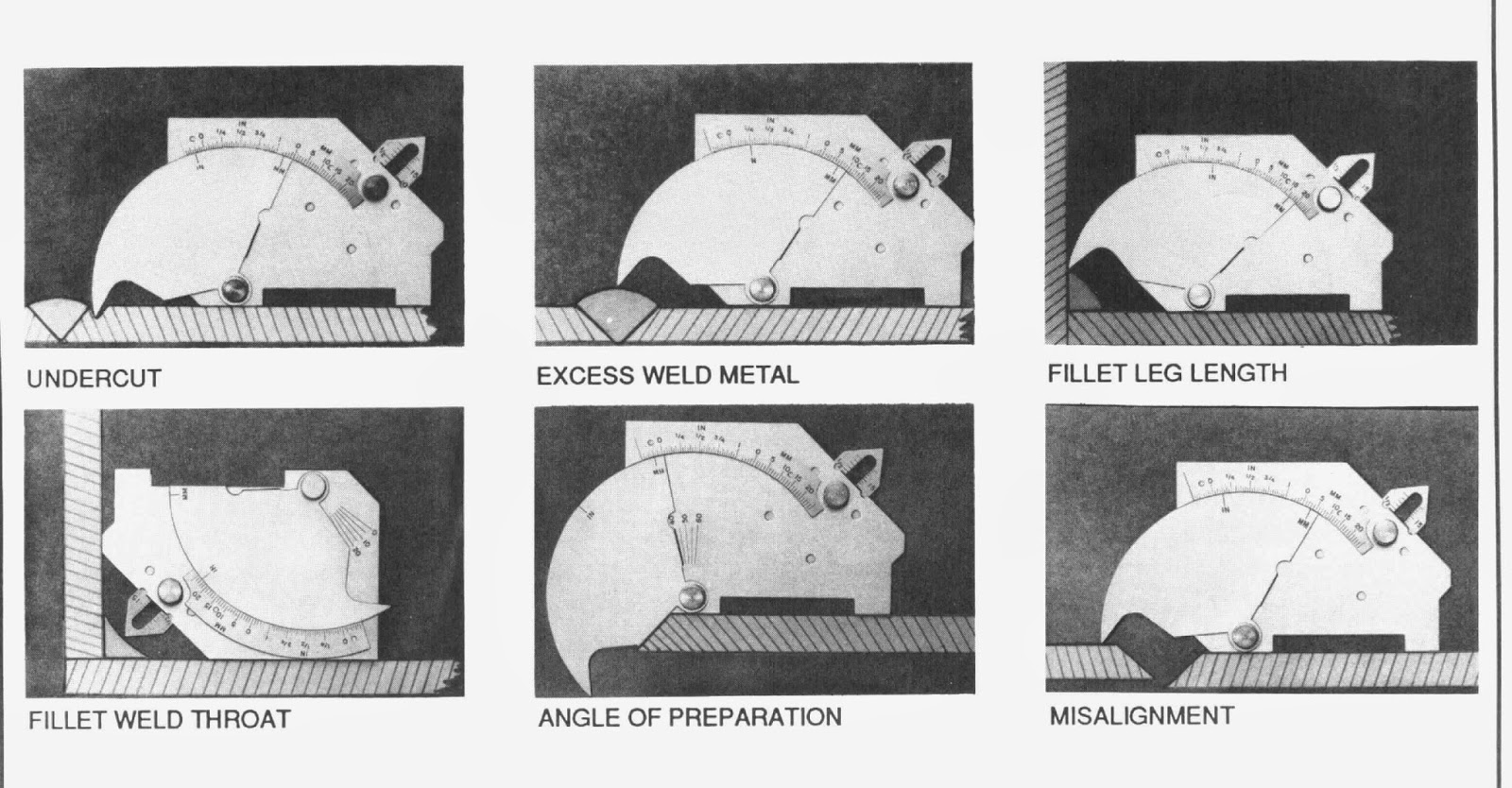

Undercut

For material less than 25mm thickness, undercut

shall not exceed 1mm, with the following exception, undercut shall not exceed

2mm for any accumulated length up to 50mm in any 300mm. for material equal to

or greater than 25mm thickness, undercut shall not exceed 2mm for any length of

weld.

For primary members, undercut shall be more than

0.25mm deep when the weld is transverse to tensile stress under any design

loading condition, undercut shall be no more than 1mm deep for all other cases.

Porosity

CJP groove in

butt welds joints transverses to the direction of the computed tensile stress

shall have no visible piping porosity. For all other groove welds and for

fillet welds the sum of the visible piping porosity 1mm or greater in diameter

shall not exceed 10mm in any linear inch of weld and shall not exceed 20mm in

any 300mm length of weld.

The frequency of piping porosity in fillet welds

shall not exceed one in each 100mm of weld length and the maximum diameter

shall not exceed 2.5mm. Exception: for fillet welds connecting stiffeners to

web, the sum of the diameter of piping porosity shall not exceed 10mm in any

linear inch of weld and shall not exceed 20mm in any 300mm in length of weld.

CJP groove welds in butt joints transverses to the

direction of computed tensile stress shall have no piping porosity. For all

other groove welds the frequency of the piping porosity shall not exceed 100mm

of length and the maximum diameter shall not exceed 2.5mm

good information thank you

ReplyDeleteThis is a very detailed breakdown of AWS D1.1 visual inspection criteria. I’ve personally found the porosity and undercut limits tricky to apply in real-world projects, so having these clear thresholds is really useful. I’m curious, have you found any common mistakes when inspecting CJP groove welds? Also, I’ve been reviewing AWS practices alongside these inspection procedures, and it’s interesting to see parallels in compliance and standards.

ReplyDelete